The Romans are known for their remarkable engineering feats, be they roads, bridges, tunnels, or their impressive aqueducts. Their constructions, many of them still standing, are a testament to their superior engineering skills and ingenuity. Roman engineers improved upon older ideas and inventions to introduce a great number of innovations. They developed materials and techniques that revolutionized bridge and aqueducts' construction, perfected ancient weapons and developed new ones, while inventing machines that harnessed the power of water. Roman engineering accomplishments generated much wealth and prosperity, improving the daily lives of Romans and helping Rome maintain its dominance in Europe and the Mediterranean for centuries.

AQUEDUCTS

Aqueducts already existed in the Near East for centuries before the construction of Rome's first aqueduct, the Aqua Appia in 312 BCE. The Romans, however, introduced many innovations which allowed them to build aqueducts on an unprecedented scale. Aqueducts consisted of conduits, tunnels and pipelines bringing water from far-away springs and mountains into cities and towns. They supplied water to the cities' fountains, latrines, public baths and houses of wealthy Romans. They were also used to power mills and other machines

Roman aqueducts used gravity, not pumps, with a slight downward inclination for the water to flow. Other innovations included the use of arcades to transport water over valleys and low-lying terrain, with the extensive use of concrete and waterproof cement linings. Another innovation was the use of settling tanks at regular intervals to regulate the water supply.

Aqueducts could be over 100 kilometers (62 miles) long. For example, the Aqua Marcia built in 144-140 BCE ran underground for about 91 km (57 miles) underground, and then 10 km (6 miles) aboveground on substructures and arcades before it reached the city of Rome.

Aqueducts had to be regularly maintained, as debris accumulated in their conduits, and leaks developed over the years. By the middle of the Principate, Rome had a large and complex water network with aqueduct cross-links that ensured a continued delivery of water even if one aqueduct was under repair.

BRIDGES

As soon as the second century BCE, the Romans built large and magnificent stone bridges such as the 135 meter (443 ft) long Pons Aemilius in Rome. The first stone bridges used stone blocks held together with iron clamps. By the mid-2nd century BCE, Romans made extensive use of concrete: bridges were often constructed with a concrete core and a stone-block facing. The use of concrete significantly increased the bridges' strength and durability. Concrete was also used to build strong piers. When piers could not be built out of rock, the Romans used “cofferdams”, which were temporary enclosures made from wooden piles sealed with clay. The cofferdams were driven into the riverbed and filled with concrete, in order to make piers.

Roman builders were also the first to fully understand the structural advantages of an arch. Bridges had arches consisting of individual arch stones (longer on one end than the other) called voussoirs, which efficiently distributed the bridges' weight. Such arched structures made bridges stronger, and allowed for much longer bridge spans. For example, the Alcántara bridge, still standing today, is 182 m (597 ft) long, with arches 29 m (95) wide and huge voussoirs weighing up to eight tons each. The hundreds of Roman bridges still in existence all around Europe are a testament to their incredible strength and reliability.

TUNNELS

The Romans dug tunnels as well for their water aqueducts and roads whenever they encountered obstacles such as hills or mountains. Tunnel construction was challenging not only because excavation could take years, but also because surveyors had to make sure that both ends of a tunnel met correctly at the center.

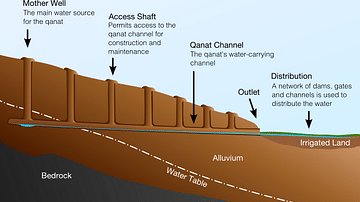

The most common tunnel construction method was the qanat method, developed by the Persians in the early first millennium BCE. The tunnel was made straight by using a line of posts laid over a hill and by digging vertical shafts at regular intervals. The shafts ensured that the tunnel did not deviate from its set trajectory and provided ventilation to the workers.

The counter-excavation method was a method used to dig through high mountains. Workers dug the tunnel from both sides of a mountain and met at a central point. This method of construction required greater planning and a greater knowledge of surveying and geometry. Builders had to constantly check the tunnel's advancing direction, for example, by looking back at the light that penetrated through the tunnel mouth. Ventilation, especially for long tunnels, was also an issue, as shafts could not easily be excavated down from the top of a mountain. The required construction times depended on the type of rock being excavated, and the tunnel's type. Tunnels involving shafts, for example, could be built much more quickly.

When the rock was hard, Romans employed a technique called fire-quenching. This consisted of heating the rock with fire, and then suddenly cooling it with cold water so that it would crack. Tunnels could take years, if not decades, to be built, even with thousands of slaves. For example, the 6 km (3.7 miles) long tunnel that emperor Claudius built in 41 CE to drain the Fucine Lake (Lacus Fucinus) took 11 years to build and used approximately 30,000 workers.

ROADS

The Romans had an extended road network stretching from northern England to southern Egypt, with a total length of no less than 120,000 km (74,565 miles) during the Empire. Roman roads were made for travel, trade, and to maintain control over the Empire's vast territories. They facilitated the rapid deployment of armies when needed.

A road's main objective was to connect in as straight a path as possible two cities often hundreds of kilometers apart. The Via Appia built from 312 BCE, connected Rome to Capua (190 km apart or 118 miles) while important cities along its path were only accessed through branch roads. The construction of Roman roads involved colossal works of engineering because not only bridges and tunnels, but also viaducts, had to be built wherever roads encountered major obstacles. Road construction also involved massive land excavation, the transport of materials for backfill and leveling over long distances, and huge hydraulic projects for water drainage and land reclamation.

Roman roads were built by first setting the curb stones, digging a long pit between them that was the entire width of the road, and then covering it with rocks or gravel. The layer of gravel was compacted and a layer of finer gravel was added. The road was then paved with large polygonal rock slabs. Because of the layer of gravel below, Roman roads were able to resist freezing and floods and required relatively little maintenance. Furthermore, the road surface had slight inclinations, so that rainwater could flow to the curbs on either side.

Milestones (from milia passum in Latin meaning 1,000 paces) were also placed along the road at intervals of one mile. They were 1.5 m (5 feet) high heavy columns which indicated the number of the mile, the distance to Rome, and names of the officials who built the road.

ROMAN CONCRETE

One of the most important Roman contributions to building technology was the invention of concrete. Concrete allowed for the construction of impressive buildings such as the Pantheon and impacted bridge and harbor construction. Roman concrete or opus caementicium was invented in the late third century BCE, when builders added a volcanic dust called pozzolana to mortar made of a mixture of brick or rock pieces, lime or gypsum and water. Pozzolana which contained both silica and alumina, created a chemical reaction which dramatically strengthened the cohesiveness of the mortar.

Rome underwent a period called a “Concrete Revolution”, which saw rapid represented advances in the composition of concrete. For example, Roman builders discovered that adding crushed terracotta to the mortar created a strong hydraulic mixture which could be used as waterproof material for cisterns or other constructions exposed to the weather. Romans also mastered underwater concrete by the middle of the first century CE, which allowed for the construction of harbors such as the one in the city of Caesarea. Underwater concrete was achieved by mixing one-part lime with two-parts volcanic ash, and placing the mixture in volcanic tuff or in small wooden cases. The mixture would then be hydrated by seawater to trigger concrete's heat-releasing / hardening chemical reaction.

MILLS & WATER DEVICES

The Romans had mills that they used to grind grain and produce flour. These mills generally had a horizontal axle attached to a shaft passing through a lower millstone and turning an upper millstone. The space between the millstones was carefully adjusted by a teetering mechanism so as to control the fineness of the powder produced. The most basic mills used human or animal power. For example, the mola asinaria dating back to 300 BCE was a basic rotary mill driven by slaves or blindfolded horses, donkeys, or mules.

The Romans also invented the watermill with either a horizontal or vertical water wheel in the mid-third century BCE. Watermills used a river or high-pressure water from a tall reservoir (or a nearby aqueduct). The power of the water hitting the wheels was often adjusted by a system of tanks and pipes. Vertical waterwheels were the most complex, as they converted the vertical rotation of the water wheel into the horizontal rotation of the shaft turning the upper millstone. The Barbegal aqueduct and mills built at the end of the first century CE, had water running through a 19-meter downhill path, driving 16 individual water wheels. The mill was able to process about 3 tons of grain per hour. It employed hundreds of people and produced enough flour to supply up to 40,000 people per day.

MINING TECHNOLOGY

The Romans were the first to use advanced technology in mining operations. Roman mining sites often had a number of aqueducts constructed around them with giant tanks and water-powered machines such as stamp-mills and trip-hammers. The giant tanks were used in a mining method called hushing. Hushing consisted of unleashing large quantities of water to wash away earth and expose valuable mineral rocks below. In another mining method such as fire-quenching, water from these tanks was released to fracture rock which had been previously heated.

Water-powered stamp-mills and trip-hammers were used to crush the extracted ore into small pieces before being further processed. Traces of the mining technology used by the Romans can still be found at sites such as Las Medulas in Spain and Dolaucothi in Great Britain. The Dolaucothi site had no less than five long aqueducts.

WEAPONS

The Romans had formidable weapons that for centuries gave them an advantage in the battlefield and allowed them to conquer vast territories. Artillery weapons such as the ballista and the onager, used in both defensive and offensive roles in siege warfare, were the most terrifying and technologically advanced weapons in the Roman arsenal.

The ballista (from the Greek word ballistra, meaning crossbow) originated in Greece, and consisted of two horizontal crossbow-like arms inserted in a twisted rope made of sinew, horsehair or gut, attached to a rectangular wooden frame. It had a slider attached to a vertical stand passing through the rectangular frame which soldiers loaded with lead darts or heavy spherical stones. The ballista was set to the armed position by pulling back the bowstring with a pair of winches.

Roman engineers significantly improved the ballista's design by adding a number of metal components which not only made the ballista lighter and easier to assemble, but also improved its accuracy by increasing its power by approximately 25%. The largest ballistae were also the most powerful. They could have arms 1 to 1.2 m (3 to 4 ft) in length, and launch darts to a distance of approximately 450 m (450 to 500 yards). The ballista was very accurate, especially at a close range. It could easily pierce a soldier's body armor with enough power to kill him instantly. Roman engineers also invented the carroballista, a ballista mounted on a cart that added mobility to the weapon. It gave each legion massive firepower on the battlefield, since as each legion pushed along 55 of these mobile ballistae into battle.

The onager was a one-arm torsion catapult which could launch much heavier projectiles than the ballista with precision, although with a lesser range (approx. 300-400 m). While the ballista had many moving parts that could break or fail, the onager had a simpler design, rendering it more reliable and easier to operate. It consisted of a large horizontal frame firmly placed on the ground, and a vertical frame with a padded buffer on the front. The horizontal frame had stretched, twisted ropes made of animal hair or sinew. An arm with a sling holding the projectile was placed on the twisted rope bundle and pushed down against the ropes' tension with a windlass. The arm was then released by a trigger mechanism releasing the tension and hurling the large projectile (it could be a spherical stone of up to 25 kg in weight), usually set alight with a combustible substance. It's impact and subsequent fires could smash into enemy fortifications and cause great devastation.

The Roman onager's design is even considered by scientists to be more ingenious than the one-arm catapults of the Middle Ages because of its sling, which increased the effective length of the slinging arm without adding any significant weight. The Romans could not wheel these large onagers into battle because they weighed up to four tons. They were instead built on-site, on padded platforms, so that their recoil would not grind the earth underneath and render them unstable.