The British Industrial Revolution transformed life at work and at home for practically everyone. Noise, pollution, social upheaval, and repetitive jobs were the price to pay for labour-saving machines, cheap and comfortable transportation, more affordable consumer goods, better lighting and heating, and faster ways of communication.

Any shortlist of inventions is bound to be far from complete, but the following have been chosen not only for what they could do but also for how they permitted other inventions to become possible and how they transformed working life and everyday living for millions of people. The period under consideration is also important and here is taken as 1750 to 1860. With these criteria in mind, the top 10 inventions of the Industrial Revolution were:

- The Watt Steam Engine (1778)

- The Power Loom (1785)

- The Cotton Gin (1794)

- Gas Street Lighting (1807)

- The Electromagnet (1825)

- The First Photograph (c. 1826)

- Stephenson's Rocket (1829)

- The Electrical Telegraph (1837)

- The Steam Hammer (1839)

- Mass Steel Production (1856)

The Watt Steam Engine

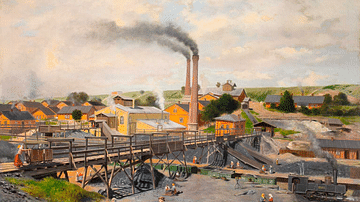

The steam engine, which harnessed power from the expansion of heated water, is often cited as the single most important invention of the Industrial Revolution, principally because so many other important subsequent inventions used it as their power source. The steam engine was born from the necessity to pump out flooded mine shafts and enable deeper mining. The first steam pump was invented by Thomas Savery (c. 1650-1715) in 1698. In 1712, Thomas Newcomen (1664-1729) perfected his more powerful steam pump to drain coal mines of water in Dudley in the Midlands.

To make the steam engine more useful for other purposes, it had to be made more efficient both in terms of fuel consumption and power. The Scottish instrument maker James Watt (1736-1819) and Matthew Boulton (1728-1809) kept tinkering with the workings of the steam engine until, in 1778, they had perfected a separate condenser to vastly increase the engine's efficiency. Power was also increased by the steam powering the piston down not just up (hence its name, a double-acting engine), increasing the 'horsepower', a term coined by Watt. The engine also had its power converted to a more versatile rotary motion using a flywheel. Using just one-quarter of the fuel of Newcomen's engine, Watt's engine was cheap enough to use almost anywhere. Steam engines kept on evolving, notably with the expansion steam engine, and they benefitted from ever-better tool machinery that could make stronger and better-fitting parts.

By 1800, Britain boasted over 2,500 steam engines, most of them used in mines, cotton mills, and manufacturing factories. 500 of these engines were made by the Watt and Boulton factory in Birmingham. Every walk of life was affected. Steam now powered fountains, threshing machines, sewage pumps, and printing presses. Essentially, any work that required pushing, pulling, lifting, or pressing could be made much more efficient using steam-powered machines. Steam engines were harnessed for trains and steamships, and, aptly, all these uses caused a boom in the coal mining industry, which had been the origin of the machine in the first place.

The Power Loom

The textile industry in the British Industrial Revolution was transformed by machines. The power loom weaving machine was invented by Edmund Cartwright (1743-1823) in 1785. The machine doubled the speed of cloth production and meant that skilled handweavers were no longer needed. The fully automated machine only needed a single worker to change the full spindles. The power loom was first used effectively in factories owned by Richard Arkwright (1732-1792). The British government awarded Cartwright £10,000 in 1809 in thanks for the significant contribution the power loom made to British industry. Other inventors improved the efficiency of Cartwright's loom, such as Richard Roberts (1789-1864) who made a more reliable iron version in 1822. Textile factories everywhere were not slow to equip themselves with large numbers of power looms. By 1835, there were 50,000 power looms in use in Britain, and factories could produce cloth cheaper than anywhere else in the world.

The spread of the power loom meant that inventors were obliged to come up with better spinning machines to provide sufficient yarn for the insatiable looms. Machine operators no longer needed any textile skills and were there to only make sure the machines kept running, often 24 hours a day. New jobs were created as more factories sprang up. Textile products became cheaper to buy for everyone, and supply industries like cotton plantations and coal mines boomed. In another knock-on effect, the abuses of workers in the factory system by unscrupulous employers created the trade union movement to protect workers' rights and health.

The Cotton Gin

Now that spinning and weaving could be fully mechanised, the speed and quantity of textile production increased enormously. What was needed next was to provide the ever-hungry machines with enough raw material to work with, cotton, in particular. Cotton was picked, sorted, and cleaned by hand, usually using slave labour on large plantations in the southern United States. Eli Whitney (1765-1825) from Massachusetts, moved to a cotton plantation in Georgia where he created a way to speed up cotton production. The time-consuming process of separating the sticky seeds from cotton balls was now done by Whitney's Cotton Gin ('gin' meaning 'machine' or 'engine'), which he invented in 1794.

First powered by horses or water wheels, the cotton gin eventually harnessed steam power. The machine pulled raw cotton through a comb mesh where a combination of revolving metal teeth and hooks separated it and removed the troublesome seeds. A single cotton gin could process up to 25 kg (55 lbs) of cotton every day. As cotton production rocketed, so more and more slaves were used on the cotton plantations to pick the cotton balls that fed the insatiable gins. The machine was so successful, it was illegally copied by plantation owners everywhere. The slave population in America rose to nearly 4 million by 1860. Cotton was exported far and wide, the USA accounting for 75% of the world's cotton production. In Britain in 1790, cotton accounted for 2.3% of total imports; by 1830, that figure had rocketed to 55%. British textile mills worked the raw material and exported it out again with such success that cotton textiles accounted for half of Britain's total exports in 1830. As the historian R. C. Allen notes, in global terms, "Cotton was the wonder industry of the Industrial Revolution" (182).

Gas Street Lighting

The dimness of nighttime lighting, traditionally provided by burning oil or tallow candles, was finally lifted by the invention of gas lighting. Around 1792-4, the Scotsman William Murdock (1754-1839) discovered that coal dust gave off a gas that could be ignited. Murdock successfully used gas lights in his foundry in Birmingham. The idea to use coal gas for street lighting was pioneered by the German inventor Frederick Albert Winsor (1763-1830) from 1807. Winsor spectacularly demonstrated the potential of his idea by setting up gas streetlights from Pall Mall to St James' Park in London. The demonstration caused a sensation with the public, and Pall Mall received 13 permanent gas-lit lampposts, thus becoming the first street in the world to be so illuminated. By around 1820, London had 40,000 gas streetlights.

The addition of light to previously dark streets transformed people's habits. No longer seeming quite so dangerous at night, more people ventured out to restaurants and places of entertainment. The idea quickly spread around the world, with Baltimore becoming the first city in the United States to use coal gas street lighting in 1816. In 1820, Paris installed its own gas lighting.

The Electromagnet

The Canadian engineer William Sturgeon (1783-1850) was inspired by the work of the French scientist André-Marie Ampère (1775-1836) and the Danish physicist Hans Christian Ørsted (1777-1851) to create the first electromagnet in 1825. The device was a horseshoe piece of iron within a coil of wire that could carry electricity and so magnetise or demagnetise the iron. The magnetic force created could then be used to lift an object, but when Sturgeon invented the commutator, his electromagnet could now drive a motor making it a much more versatile power source. This power source has been used in everything from the telegraph (see below) to today's washing machines.

The First Photograph

The first photograph was taken using a camera obscura by the Frenchman Joseph Nicéphore Niépce (1765-1833) in 1826. The photograph, titled View from the Window at Le Gras, is a little blurred, but it is the oldest surviving photograph of a real view. The camera obscura, essentially a box with a small aperture covered by a lens, was not new since artists and engravers had been using them to help their work. What was new was Nièpce's idea to permanently capture the image projected through the lens onto light-sensitive silver chloride-coated paper. This new technique was called heliography, but it had two significant drawbacks. The first problem was the image faded away into black when exposed to light. The second problem was the image was captured in negative (light areas in real life were shown dark and vice-versa). Niépce solved the problem using a bitumen solution to cover a glass or pewter plate, and so he captured the view from his window. The photograph idea was further improved by Louis-Jacques Daguerre (1789-1851), who used copper plates treated with silver to capture a positive image. The daguerreotype was bought by the French government and made public, which resulted in a boom in photographic studios. In 1840, the English inventor William Henry Fox Talbot (1800-1877) made the first paper negatives from which any number of prints could be made.

The arrival of the photographic camera not only permitted people of all classes to have their portraits taken but it revolutionised art. Many fine artists no longer wished to recreate the world around them as accurately as possible because the camera could easily achieve this. Instead, artists strove to capture the momentary effects of light and colour or communicate a certain emotion in their work. The arrival of the camera was one of the reasons for the development of impressionism and symbolism in the last quarter of the 19th century.

Rocket

The first railways were short distances of tracks used at mines to transport material to where it could be shipped away. George Stephenson (1781-1848) owned a company in Newcastle that specialised in building railway trains to transport coal like this. Stephenson saw that passengers might travel in the same way as coal and designed the Locomotion 1 train engine, which was powerful enough to pull carriages. Locomotion 1 transported the first steam railway passengers from Stockton to Darlington in the northeast of England in 1825.

George's son Robert Stephenson (1803-1859) then outdid his father with Rocket, a pioneering steam-powered locomotive invented in 1829. The locomotive won the Rainhill Trials that year to see which machine would pull carriages on the world's first intercity line between Liverpool and Manchester. Rocket was the first powerful and reliable locomotive; it incorporated many new design features such as a multitubular boiler and a blast pipe that gave more power than rival locomotives. Rocket, capable of (at the time an amazing) 48 km/h (30 mph) top speed, deservedly won the Rainhill Trials cash prize of £500 (around £42,000 or $50,000 today). The Liverpool-Manchester line was soon carrying 1,200 passengers a day. It showed the way forward to revolutionise travel not only in Britain but worldwide.

'Railway mania' saw 24,000 kilometres (15,000 mi) of rail lines built across Britain by 1870. From 1848, passengers could travel from London to Glasgow in 12 hours, as trains reached speeds of 80 km/h (50 mph), a journey that would have taken five days or more by stagecoach. The railways created a boom in the production of coal (for fuel) and iron and steel (for rails, bridges, and trains). People began to take excursions to new places, especially the seaside. A massive quantity of jobs was created, everything from station masters to toilet cleaners. Letters could be delivered anywhere in Britain the next day, and the millions of tons of freight carried meant consumer goods became cheaper.

The Electrical Telegraph

The railways greatly improved the speed not only of travel but also communication, as sacks of letters were moved around by train. Britain introduced the universal penny post system in 1840, which permitted next-day delivery, but there was already a serious rival to postage. The telegraph was invented in 1837 by William Fothergill Cook (1806-1879) and Charles Wheatstone (1802-1875). The first telegraph machine had only 20 letters, indicated in the message sent by the slight movement of two needles (from the machine's set of five) towards a particular letter. The needles were moved by electrical impulses sent down the telegraph line connecting two machines. Short messages could now be sent quickly and were first used on the railways to communicate instructions to drivers and stations.

The first successful use of the machine was for the Great Western Railway in 1838, used between Paddington Station and West Drayton, a distance of 21 kilometres (13 miles). The cables were first laid underground but then adapted with insulation for hanging in the open air between what became known as telegraph poles. As the system was adopted across the British railway network, so for the first time it was possible to have a universal time when previously, town clocks had all varied. Consequently, the telegraph made Greenwich Mean Time (GMT) possible. Information could be sent wherever there were telegraph machines, meaning that news of events spread far quicker than previously. The speed of telegraph communication was also very useful for the police who could alert fellow officers far away of criminal activity and even to capture escaping criminals. Telegraph communication made a step forward when Samuel Morse (1791-1872) of Massachusetts, with the assistance of Alfred Vail, first put his Morse code into action in 1844. The giant steamship SS Great Eastern, designed by Isambard Kingdom Brunel (1806-1859), laid the first cross-Atlantic telegraph cable in 1866, and this now allowed fast intercontinental communication. Suddenly, the world seemed a little smaller and life a lot faster.

The Steam Hammer

The steam hammer is not the most glamorous of inventions in this list, but it was crucial to making many other inventions possible. Developed in 1839 by the Scotsman James Nasmyth (1808-1890), this relatively simple device used a steam engine to let fall (and later push) with a precision of both speed and direction a great weight capable of forging or bending large pieces of metal resting on an adjustable anvil plate. As the steam hammer could be made in any size required, metal pieces could be worked that would not have been possible by any other means. In addition, the accuracy of the hammer meant different pieces of metal could be bent in exactly the same way, essential for components of large machines like giant steam engines, trains, iron ships, heavy weapons, and bridge girders.

Nasmyth's machine was so precise he could demonstrate to visitors to his foundry that a 2.5-ton weight could crush an eggshell sitting in a wine glass and do no harm to the glass. This precision meant a steam hammer could take on smaller tasks that required more finesse, like minting coins and printing banknotes. Another advantage was the speed the hammer could operate, sometimes delivering 220 blows per minute. No matter what the operation involved, all that was needed in terms of labour was one person casually operating a simple lever. Unlike so many of the other inventors in this list, Nasmyth made a staggering fortune from the hammer which revolutionised industrial production.

Steel Production

Iron was used throughout the Industrial Revolution for all manner of machines and construction projects, but steel is far superior in strength and malleability, and it is lighter. This meant that steel was particularly useful for larger projects like bridge-building and weight-bearing items like rail tracks. The problem was that making steel was an expensive process. As so often with inventions in the Industrial Revolution, a new idea was based on a pyramid of earlier inventions and produced because of the search for efficiency and cost-effectiveness.

Henry Bessemer (1813-1898) invented a converter in 1856 that made steel production much cheaper and more reliable. The bigger Bessemer converters, filled with molten pig iron, could make up to 30 tons of steel in 20 to 30 minutes, removing carbon and other impurities by forcing air under high pressure through the molten metal. The impurities form oxides and so are separated as slag, leaving behind pure and strong steel. After Bessemer's invention, the cost of steel fell from £50 a ton to just £4 by 1875. Sheffield became one of the biggest steel producers in the world, making, in particular, railway tracks for Britain, the United States, and many other countries around the world.