The production of steel during the British Industrial Revolution became cheaper and more reliable thanks to the Bessemer converter, a type of blast furnace that removed undesirable impurities from pig iron. The superior strength and durability of steel over iron meant that the metal took over as the preferred choice of civil engineers to build bridges, tunnels, and railway tracks.

Sheffield became one of the most important steel-making centres in the world and was particularly noted for knives and cutlery. Steel being an iron alloy with 1-2% carbon, metallurgists experimented with the removal and addition of impurities in the blast furnace to come up with different types of steel with particular properties such as the very hard tungsten steel still so useful today for metalworking tools.

Iron v. Steel

The production of quality iron greatly improved during the Industrial Revolution, largely thanks to the use of coke as a fuel in the furnaces instead of traditional charcoal. Coke is made from burning (or perhaps more accurately, baking) coal in a furnace to remove as many impurities as possible, essential so that these impurities do not integrate with the molten metal in the furnace. The first working blast furnace employing coke was used in 1709 at Coalbrookdale in Shropshire, a works owned by Abraham Darby (1678-1717). Coke-fuelled blast furnaces had another important advantage: they could reach much higher temperatures than those heated using charcoal. Quality iron was now used for all manner of projects, and Britain was making 50% of the world's supply by 1850. However, there was an even better metal available: steel.

Steel is far superior in strength and malleability compared to iron. Steel is also lighter than iron and can grow stronger over time under weight pressure, unlike iron which is more brittle. These advantages meant that steel was particularly useful for larger projects like bridge-building and weight-bearing items like rail tracks. There was a major drawback, though, in the iron versus steel competition. Steelmaking was much more expensive than ironmaking since it could only be done in relatively small quantities. This situation changed thanks to the endeavours of the British engineer Henry Bessemer (1813-1898).

The Bessemer Converter

As so often happened with groundbreaking inventions in the Industrial Revolution, a new idea was based on a pyramid of earlier inventions and developments by different innovators in different places. Benjamin Huntsman (1704-1776), motivated by his search for strong but flexible clock springs, had been the first to develop crucible steel, that is steel purified in closed clay containers subject to intense heat. Making crucible steel was not at all a new process, but Huntsman pioneered a method using coke as the fuel around 1740-42 so that a purer steel than ever before could be made.

Another step forward in steel production was made by John Neilson in 1827 (patented in 1828) when he pioneered a new technique for heating the air before it was introduced into a blast furnace, known as the 'hot blast' technique, which intensifies the heat inside the furnace. Higher furnace temperatures meant metalworkers could produce purer metals but it also greatly reduced the fuel needed for the furnace and so reduced the cost of the metal they produced. Still the quantities of steel made in each furnace were not large enough for the needs of heavy industry. The search for cheaper steel was a typical case of innovation being driven by considerations of efficiency and cost-effectiveness.

In 1856, Henry Bessemer was motivated by Britain's involvement in the Crimean War (1853-56) against Russia to develop more and better steel for weapons manufacturers, particularly cannons. Bessemer spent several years and tens of thousands of pounds on research and development until he perfected a new type of blast furnace which later became known as the Bessemer converter.

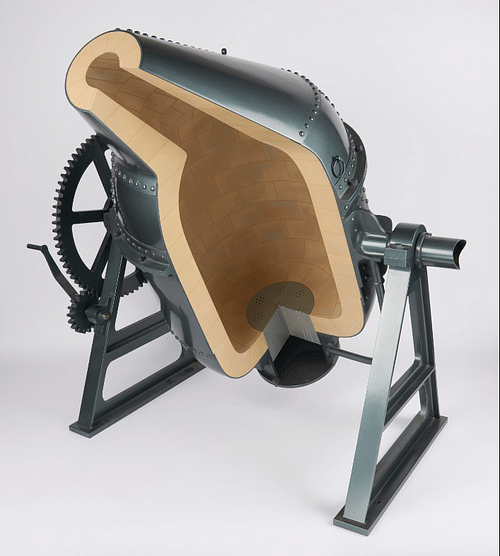

The converter was essentially a giant flask of firebrick with a steel outer casing. The flask pivoted within a frame so that it could be tipped horizontally to allow iron ore to be placed inside, put vertically for the heating part, and then tipped horizontally again to empty out the molten metal. The Bessemer converter heated pig iron (that is iron too rich in carbon to be of much value) to up to 1550-1600 degrees Celsius (almost 3,000 Fahrenheit), removing carbon and other impurities like manganese, phosphorous, and silicon by forcing air under high pressure into the base of the converter and so through the molten metal inside. The impurities form oxides when the air is injected, and so these are separated out as slag, leaving behind a pure and strong molten steel. Some impurities were actually found to be beneficial depending on what the steel was intended for; manganese in low quantities, for example, was discovered to make the metal less brittle.

The converter process creates an impressive pyrotechnic display as the converter is tipped upright, and sparks and smoke fly out from the aperture at the top (in later versions the escaping heat was recaptured to help heat the furnace below, further saving energy costs). To an expert eye, the colour of the sparks the converter emits indicates that the refining process is complete. The converter is then rocked back to a horizontal position, and the steel is poured into moulds. This final process is known as teeming, and it is one which must be conducted with care so as to not allow air bubbles to form within the steel ingots, which would weaken the metal.

The bigger Bessemer converters could make up to 30 tons of steel in 20 to 30 minutes. Previously, it had taken a whole working day to produce around 5 tons of steel. Steel was now, then, a mass-produced product. After Bessemer's invention, the cost of steel fell from £50 a ton to just £4 by 1875. By 1880, British steelworks were churning out over 1.3 million tons of steel every year. The raw ingredient of iron ore rose in production to match the massive appetites of the converters. In 1855, Britain produced 9 million tons of iron ore, but by 1875, this figure had risen to 15 million tons. Iron ore came from Britain (particularly the Cumbria region), Spain, Sweden, and Germany to feed the furnaces of Britain and, above all, the very heart of the British steel industry in Sheffield.

Sheffield Steel & Uses

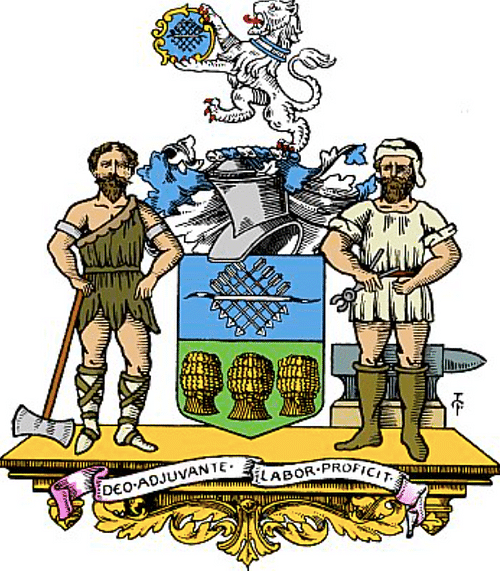

Sheffield in South Yorkshire became one of the biggest steel producers in the world and earned itself the nickname 'Steel City'. In 1770, there were just five steel works in Sheffield, but by 1856, this figure had rocketed to 135. Appropriately, the city's coat of arms (awarded in 1875) shows the figure of Vulcan, the Roman god of metallurgy. It was no coincidence that both Huntsman and Bessemer chose Sheffield for their foundries and steelworks. Sheffield was well served by fast-moving rivers that provided power via water wheels, important as a power source for the bellows that raised the necessary high temperatures in the furnaces. Another advantage of the Sheffield area was the presence of millstone grit, which could be used to make circular grindstones to shape, grind, and, if necessary, sharpen the steel.

Sheffield became world-famous for its steel and particularly its cutlery and needles. Knives and any tool with a cutting edge, like scythes, were other specialities. Better steel was particularly useful in medicine, where it was used to make surgical instruments. The flexibility of steel made it ideal for making springs of all sizes. Other successful steel products included heavy agricultural machinery and railway tracks for Britain, the United States, and many other countries around the world. The figures are astounding. Only between 1865 and 1874, Sheffield exported to the USA over 280,000km (175,000 mi) of rails. Many of these larger projects had been made possible by the invention of the steam hammer in 1839 by the Scotsman James Nasmyth. The steam hammer used steam power to precisely forge and bend huge pieces of metal, including steel.

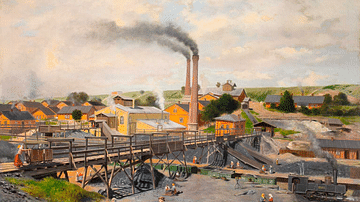

The steel industry brought jobs and money, but the impact on the environment was dramatic. The noted journalist and politician William Cobbett travelled from London to visit Sheffield in 1830 when the steel industry was still in its infancy, and he gave the following description of his experience:

All the way along from Leeds to Sheffield it is coal and iron, and iron and coal. It was dark before we reached Sheffield; so that we saw the iron furnaces in all the horrible splendour of their everlasting blaze. Nothing can be conceived more grand or more terrific than the yellow waves of fire that incessantly issue from the top of these furnaces…They call it black Sheffield, and black enough it is; but from this one town and its environs go nine-tenths of the knives that are used in the whole world. (Dugan, 66-7)

Mushet & Tungsten Steel

Steel kept on evolving. The British metallurgist Robert Forester Mushet (1811-1891) produced tungsten steel in 1868. Like Bessemer, Mushet experimented with the level and type of impurities in furnaced iron. Rather than struggle with removing specific quantities of impurities as other metallurgists had done, Mushet came up with the simple idea of removing all the impurities from the iron ore and then reintroducing specific quantities of the specific impurities he wanted. In this way, Mushet discovered that a certain percentage of tungsten greatly increased the strength and durability of the steel. The downside was that tungsten was not as malleable as other types of steel, but this was less significant given the primary use of tungsten steel – which is still the case today – where smaller quantities of hard-wearing metal are used for drill bits, cutting blades, and other metalworking tools. Another quality of tungsten is that it is extremely heat-resistant making it the material of choice for use in incandescent lightbulbs. Steel in all its forms remained the king of construction metals deep into the 20th century until it was challenged by such new lighter but even stronger materials as fibre-reinforced plastics and carbon fibre.